As you all know we don't build boats here at the shop for money, hell we don't do anything for money anymore. If someone's paying you to do something they own your body and sole and we're done with that. We also don't want any help with any building we do. Owning a boat sucks, nothing but maintenance and trouble. Building a boat however is a lot of fun and the ultimate challenge for our diminishing brain power. Even one as small as a Nutshell pram will tax most of us. So you see why none of us will allow any help; if you're doing it for the challenge you sure don't want anyone '' helping" you. Even when it comes to heavy lifting you need to figure out how to rig it right. We did have one exception: Here's the story.

|

|

Back in about '04 or '05 the life guards at Jacksonville Beach commissioned Roger Allen then of the Cortez Maritime Museum to build them a traditional wooden surf boat. It took a while to finish the boat because it was made by the volunteers who played at the boat shop there. Roger uses all building as a learning experience so speed isn't the driving factor. It got finished and was delivered in '07 and was really a beautiful boat.

|

|

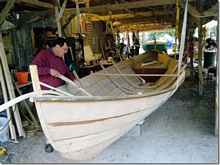

That first boat turned out so well that a second boat was commissioned but the arrangements were different from the first one. I don't know the exact details but this one went a lot slower than the first one; so slow in fact that eventually Roger asked me if we could finish it for them here at our shop. It had the basic shell finished and Roger is a good friend so we took it on. This was the first time we had done anything as a group and it was shocking at how fast and easy we whipped it out. We usually like to spend more time thinking about it rather actually building, but this time it was just get it done and out fast. It was basically Howard, Jim and me and things got done with a minimum of fuss or conversation and we had it pretty much finished and ready for paint in just a few weeks.

|

|

But then we ran into a little snag; one night the whole shop caught on fire and burned up. The fire was caused by an old radio shorting out. It was kind of a shock but not as bad as you would think, turned out that I had great insurance and they replaced everything better than new and even threw in some extra just for the hell of it. We got a new shop and new tools, just imagine me handing you ten thousand dollars go out and get anything you think we need and more if that runs out. Unfortunately, there was one thing that we couldn't buy, the surf boat had somehow completely disappeared. It turns out that okoume plywood burns like flash paper and the whole boat simply vanished. These pictures were taken the next day after the fire and the one with the clear space is where the boat was sitting, no clean has been done, it's just all gone. The concrete block you see is the one the boat was sitting on in the previous picture with Jim working.

|

|

The fire happened in April '10 and we had a lot to do, what with spending money on all kinds of neat new tools; all power, no hand tools for god sake. We're not living in the dark ages. Fland Sharp, the mayor over there was very accommodating with us but eventually we knew that awe owed him a boat. Again we figured that we better work together to get it done. The picture of the new molds being set up was taken on Dec 1 2010. This boat came together so fast it was like watching a time lapse movie. We would set up jigs and whip out parts like a well oiled machine, mostly Howard and Jim, I had to take the pictures.

|

|

Here it is three weeks later with Jim spray painting the inside. You heard me, three weeks. I used to wonder how they whipped them out in the old days and now I see how. If a crew knows what they're doing and are all getting with it without any standing around arguing about what to do next it really goes fast; one cutting, one scarfing, one fastening can put in the pieces like a boat model. And since we had done the other one that burned we know what to do. The floor boards are always the biggest pain because of the custom fitting required for every board. The usual time frame for just one of us building a boat like this would be anywhere from six months to a year depending on how much "thinking" is needed. That's the fun part.

Helen and I drove it over to Jax Beach, that's Fland on the right. They were happy with the boat and we were done with all that, sort of.

|

|

We didn't come home empty handed. The first boat had been in use for a couple of years and it was a real "rode hard and put away wet" kind of deal. They don't have any facilities for taking care of wooden boats there and it was a mess. It had cracks and splits and a little rot and was basically a basket case ready for a Viking fire. Helen and I headed home with the trailer (it's about 200 miles) and I got a mile out away and called Fland and told him that I was coming back to get the first boat to take home to fix for them. He said that they had no money to pay for it and I told him that we don't work for money anyway and I just couldn't leave it there like that. We had nothing to do with that first boat but it looked so good, what the hell. You should have been there when I showed up back at the shop with this boat. It was not a warm welcome but those guys are suckers just like me. One of the problems is that they move and launch these boats by dragging them across the beach behind a jeep and run them up one the beach in the surf and roll them in the surf; you know the usual boy stuff. We stripped it back down to the basics and rebuilt it stronger. Hand Jim a pry bar and big hammer and stand back.

|

|

On the bottom we installed a full length keel of hard pressure treated pine and two short runners and covered all with several layers of Kevlar to help with the abrasion on the beach. A complete rebuild of the inside and a paint job and it was ready to go home. We talked Stan into taking it this time and wouldn't you know that when he got home he brought the other boat back with him. What the Hell is going on here? It seems that the boat we had made was taking a beating like the first one did but the final straw was that they had rolled it in the surf and put an oar right through the hull. We fixed it and reinforced it like we did the other one and called Fland to come get it and not bring any of them back. Being the great guy that he is, Fland showed up a few weeks later with a pickup truck completely full of cases of Sailor Jerry rum, our favorite. He had evicted tenants from a bar he owns and brought us the stock as payment, what a deal. Turns out that we will work for booze. We've seen Fland several times since but not for these boats, you may see him and his lovely Brenda at Cedar Key this May.

|