|

design by Warren D. Messer - Seattle, Washington - USA |

If you like to build paper models of boats, you will be glad to know that Mr. Messer has made available a PDF file which can be printed and cut out for a model of his Nuthatch Pram. Download HERE |

This design is my first and the result of endless hours spent before a computer learning the relationship between curves on a flat 2D screen to the curves in a 3D model. I had tried several 3D computer modeling programs that I downloaded from the internet, but none of them could give me the 2D printout that I needed for constructing the 3D model and then scaling up to full sized panels for layout on 2D plywood sheets.

I wanted to design a boat that could be built anywhere in the world where plywood could be found and not require any kind of mold or backbone frame to be built first. If you can't find the epoxy and fiberglass tapes and cloth in the back waters of the world; all the non-wood stuff to make one boat will fit in a cubic foot and you could carry it with you. It had to be stitch and glue and easy enough to layout and construct so you could do it on the bow of your boat, dock, or beach, and mostly without power tools.

The boat also had to perform in adverse conditions, overloaded, and powered by oars. I wanted to give the boat enough freeboard to keep it from being swamped in waves, but not so high that they would act as sails. Enough width for stability, but not become a pig to row. Enough Vee in the bottom so it would track well and not waste the rowers energy keeping it in a straight line, and with plenty of arc in the keel and chines to give it strength. I wanted a pram, so the most volume could be put in the shortest length, and I wanted enough Vee above the waterline in the bow to help it cut through the water. Most of all I wanted it to look good. Form is a function, and my motto is "stitch and glue and stylish too".

Once I had an idea of what I wanted, my routine became, design for hours on a vector drawing program, print it out, glue it to some cardboard, cut out the pieces, and put the hull panels back together again with masking tape. Then figure out what went wrong with that design and do it all over again. I ran out of cardboard and was checking the recycle bins, and begging my close friends and neighbors for any cereal boxes they had. Finally after 15+ attempts, things started to come together. It only took another 10+ rounds on the keel lines to complete the design as a finished model. Then scale it up to a 4 inch equals 1 foot model for error checking and final fit, followed by hours more of scaling up the dimensions from the plans to construct the real boat. While building the full sized boat, only one line needed to be adjusted and the finial lofting sheets corrected. Things go much quicker now and I can create a completely new design after about a dozen try's.

I am very happy with the shape and fit of the boat and will not be making any changes to the design. The original boat had a side to side middle seat which was fine for one person, but the boat could not be balanced with someone in the stern seat. The design and hull #1 were changed to their current form with the fore and aft center/bow seat combination. With one person onboard, it glides along with little effort, sits high with little wetted area, and tracks straight, and weighs in at around 72 pounds.

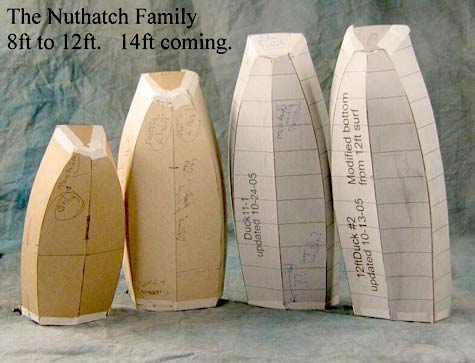

The design has been scaled up for works in progress, with lengths of 10, 12, and 14 feet. The 14 foot version has a deep, surf bashing/cutting bow and vee bottom.

Bio for Warren D. Messer

I have been around small boats most of my adult life, with a hitch in the Coast Guard, and racing sailboats in the ½ and ¾ ton IOR classes in Puget Sound. I also had a Coronado 15 for several years that I used for trailer sailing in and around the Northwest.

I then got into white water kayaking for about 20 years, with lots of different boats, plus owning a few canoes and sea kayaks along the way. This was followed by the armchair, over the bounding seas, sailor period, which I am currently in. All that reading lead to the debate over hard shell or inflatable for the ship's tender. After seeing the prices and life spans of an inflatable, I woke up in the world of owner built small wooden boats. Then to the question of which side do I stand on, modern or traditional? I went with quick and easy.

The first design was for me, and I wanted something that could be easily repaired or replaced anywhere in the world. So I started searching online, and in lots and lots of books for the perfect design. Seek and you'll wish you hadn't. I wanted a boat that had the lines of the old classics, but not all the work to build just the jig, and then still have to make the boat; or to have the excessive boat weight of traditional plank construction. I wanted simple, light, and strong; and that's stitch and glue. Like Queen Victoria, I was not amused with what I saw being offered and decided to clear my own path through the forest. My degree is in Forest Engineering from the University of Washington and I wanted to apply some of my wood structures education to the process of designing a boat. Light and strong and pleasing to the eye; stitch and glue, and stylish too.

I have a fleet of boats on the drawing boards and coming down the ways, and will be posting them at DuckWorks as soon as they launch.

Thank you

Warren D. Messer

Plans for 8ft Nuthatch are available from Duckworksbbs.com

They include the following PDF files:

- Printable Paper model - Free Download

- 44 page generic instructions

- 8 pages of detailed drawings

Each set of plans comes with a printable paper model (left)

as well as many colorful and concise pages of instructions -

perfect for the first time builder.

|