|

Duckworks entry Sails!

- Duckworks entry Sails!

-

Sailing bits, and

polytarp sail making.

|

This

shows how the poly tarp is cut to get the sail to fit. Poly tarp is

easily fastened to itself with double sided exterior carpet tape. It

is fiberglass reinforced and exceptionally strong. You can stitch on

top of it if you're a "belt and suspenders" kind of person. The

photos below show using a larger tarp, but you could start this

way. |

|

Here's the sketch with side

lengths. |

|

I

marked the length of the sail's sides on wood strips and then did a

trial layout. |

|

I use

3/4" PVC pipe to layout the curves of the sail edges. Here I'm

drawing the shape of the head or top edge of the sail. This edge

will be attached to the upper spar by rings or ties. I held

the pipe in position with weights then traced its curve

lightly. (Head or top of the sail curves out about 3 inches and

the leech or trailing edge of the sail curves in about 2 inches.) If

she needs more shape I'll try the little edge pleats that Dave Gray uses. As you might suspect, I try

simpler first and get complicated only if necessary;-) |

|

After

tracing the pipe, I apply double stick fiberglass reinforced carpet

tape on the outside of the line. An artist brayer helps apply it

smoothly. |

|

I

then cut along the outer edge of the tape. (A foam pad or knee pads

is handy for this part. You'll do a lot of crawling

around.) |

|

|

I use

the brayer again to form a crease along the inner edge of the

tape. |

|

Then, a few inches at the time the backing is peeled

and the tape is rolled tight. |

|

Along the head of the sail place 1/4" bolt rope to

help take up some of the stress and also keep the sail rings from

pulling through. Some put bolt rope around the whole sail, but

I've been told the smoother the air flow over the leading and

trailing edges of the sail the better. Besides that fiberglass

reinforced tape lends amazing stretch resistance to the sail

material. |

|

I

have previously melted through the sail just inside the bolt rope

with my soldering iron, but this time I used the tip of my glue gun

to melt it slightly, followed by an awl. These rings are actually

sold for shower curtains. (OK, don't laugh, they work!) If these

don't fall under the catagor of "fasteners" in the rules, short

lengths of the 1/4" rope would work fine too. Though I couldn't make

hot melt glue work for the seams, it seemed to work fine for the

corner reinforcements, and tacking down loose

corners. |

|

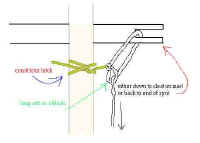

This shows a "fair

lead" created by drilling a hole through the tiller handle then

rounding the edges with 3/8" quarter round a router bit. The main

sheet and the tiller can be controlled with one hand, and the hole

is positioned so you can pinch the sheet between the tiller and the

top of the rudder head. Lift the tiller and release and the line

runs free. Regular pintels and gudgeons could be used. Here I use

the double taper block approach. If loose footed, skip this and

sheet to the transom corners for best sail

trim. |

|

Within the rules I could take the taper trim pieces

from the mast, glue the sawn faces together making it a rectangle

then laminate into a 2x6 10" long. (Could happen!)

If this seems too far

fetched materials use, substitute stainless or bronze pintels and

gudgeons - but this wedge gizmo works great!

|

In this

10" piece of 2x6, I cut a 7/8" deep saw kerf down the center. The yellow

dotted lines shows how I taper the insert. In instrument building this

trick is used to join necks to bodies. When you insert it it will snug it

up against the transom. Way easier then hanging over the stern of a small

boat trying to line up pintels, I promise! In this

10" piece of 2x6, I cut a 7/8" deep saw kerf down the center. The yellow

dotted lines shows how I taper the insert. In instrument building this

trick is used to join necks to bodies. When you insert it it will snug it

up against the transom. Way easier then hanging over the stern of a small

boat trying to line up pintels, I promise!

This could all be done with a hand saw,

but I used the table saw. I don't own a taper jig. But here's an easy way

to cut a taper using a scrap of plywood. I set the saw to 25 degrees and

clamped the fence about 5 inches away. I ran a scrap of plywood throught

the saw. I then lined the cut edge of the ply up with marks I made on the

BOTTOM of the wedge stock. I stapled it in place with 1/2" staples and ran

in through the saw. I then pulled it off and stapled it to the other

line. Works great. This could all be done with a hand saw,

but I used the table saw. I don't own a taper jig. But here's an easy way

to cut a taper using a scrap of plywood. I set the saw to 25 degrees and

clamped the fence about 5 inches away. I ran a scrap of plywood throught

the saw. I then lined the cut edge of the ply up with marks I made on the

BOTTOM of the wedge stock. I stapled it in place with 1/2" staples and ran

in through the saw. I then pulled it off and stapled it to the other

line. Works great.

|

Here's the wedge with the seatbelt webbing trial fit

in the saw kerf. Ultimately I glue it in with PL Premium and

anchor it with some small ring nails for "safes." Is seatbelt a

fastener? Could melt a bunch of short pieces of 1/4" rope

together..... hmmmm.... |

|

Here

are the receivers trial clamped to the transom. |

|

I shortened

the receivers so the wedge is longer so I could tap it loose if it

should get stuck. I've also rounded the edges and sanded them

some. |

|

The

leeboard idea I got from my friend Richard Frye. It will work with

internal chine logs or stitch and glue. The board bolts flat against

the side with a plastic spacer to reduce friction. It "bump" stops

against the gunnel in the down position. |

|

There is a simple 1/2" hole

drilled in the top of the mast for the halyard. It is rounded with a 3/4"

quarter round router bit. Just above the mast partner two wooden cleats

are screwed on either edge of the mast. One is for the halyard and the

other for the down haul.

A simple snotter tensions the

sprit boom.

A simple snotter tensions the

sprit boom.

|

Here

she is rigged, in the sprit boom version. |

In spite of no wind I was determined to

sail. In spite of no wind I was determined to

sail.

So

we went out. So

we went out.

We came back. The breeze was almost

theoretical it was so light, but she slipped along nicely. Since then I've

had her out in a few good breezes and according to my Garmin GPS we hit

7.5 knots quite a few times. We must have been planeing though I didn't

feel it. We came back. The breeze was almost

theoretical it was so light, but she slipped along nicely. Since then I've

had her out in a few good breezes and according to my Garmin GPS we hit

7.5 knots quite a few times. We must have been planeing though I didn't

feel it.

She patiently awaits a

captain...

She patiently awaits a

captain...

Shucks, if only I hadn't

run out of time, I could have used that extra 8x10 polytarp for a camping

cockpit tent!

|

![]()