|

|

| January

- February - March - April - May - June - July

August - September - October - November - December |

Christmas Cards

Hi again guys,

We came across some nifty Christmas cards yesterday

at our local (small town) marine chandlery. Turns out that they’re

produced by an artist who lives in Brentwood Bay BC, only a

few miles from us.

Her website is: https://www.clarkandmihaly.ca

- and I’ve just discovered that she has an Alden

Malabar Jr.

I have no vested interest in this, other than

providing a link to what I consider some really nifty designs.

Cheers J

George

|

|

| Anchor

Light

I made a removeable anchor light

from one of your LED stern lights - #IL-560-2113.

here is what I did: - I drilled an extra hole about midway of

the tube and inserted the black eyebolt that came with the light.

I installed an "S" hook in the bottom hole of the tube

and attached a "tail rope" to it.

To use the light, I simply hook

the mainsail halyard to the eyebolt in the center of the tube

and pull up the mast all the way to the top,,,,, secure the halyard

and then pull down on the tailrope which in turn raises the light

(180 degrees) and it is "above" the top of the mast,

allowing 360 degrees visibility.

wha lah!

Bill Tosh

|

|

| Curt-A-Loader

This may be a little lengthy but I have to explain

what led to my curt-a-loader.

I use Malone seawing saddles. When I use 2 sets of them, for

shuttling, they overhang each side of the vehicle. I wanted to

buy a wheel loader but the easy ones that do not need to be attached

to anything all fit in the top crack in the rear hatch door. For

me the wheel would be too far off center of the cradle. Also,

there are hinges in my rear door that won’t allow proper

placement for anything other than loading in the middle. The way

I made mine allows for all offsets and obstructions and the kayak

can be slid straight on to the saddle. The loader does not need

to be attached. It simply sits on top of the roof. After the boat

is loaded simply remove the loader. It just sits on the roof as

if you’re laying it on a table. That’s it, done.

|

|

The 2 small nubs that stick up prevent the loader from sliding

forward while loading. The extra length beyond those slip under

the cross rails. When the boat is unloaded the weight of the boat

raises this (there is very little extra room to begin with) to

“hold” on to the under side of the cross rail, preventing

the loader from sliding out of position. I don’t know if

I really need the nubs or the extended portion as I never had

this move on me at all. The length from the nubs to the wheel

is adjustable (hidden under pipe foam) to fit any SUV. The adjustment

device is just pipe couplers with whatever length pipe you need

between them. These are screwed in only. This turned out to be

not needed also but when I built it I did it this way just incase….It

could come in handy if I were to get a new SUV I suppose.

You can see this is made of pvc pipe and pipe insulation. I used

pipe insulation tape to form the tapers on the wheel. All the

joints are glued and screwed. The axle on this is ½”

sch. 80 pvc with a 1” pipe over it. I angled the wheel to

be just beyond the back window. This is what makes the loader

tilt to lock in position when removing the boat. The rest is ¾”

sch. 20 pvc pipe. I loaded 70 lbs with it. If I were to load heavier

kayaks I would use sch. 40 or 80 depending on our needs.

The size to fit my Tucson is about 14” x 24”.

The pictures are pretty clear on how it all goes together and

where it sits on the SUV. I don’t have my saddles on for

the pic but the wheel is just slightly above the saddle for smooth

sliding.

The first time I used it I couldn’t believe how simple

it was. I had “j” cradle autoloaders and that was

not nearly as easy as this. Just as you would any rear wheel loader

device, I lift the front half of the boat and place it on the

wheel. Half the boat having a pivot at the rear makes it very

light. After the bow is on the wheel, the wheel becomes my second

person. Than I just lift the stern, again half the boat and having

a pivot at the wheel is very light, and push the boat forward

to desired position.

Depending on materials used, this type of loader is enough to

load any type of boat that can be loaded on a roof.

Curt G |

|

| Chris Craft Runnabout

click image for larger view

I'm restoring a vintage 1948 19'

Chris Craft Racing Runabout. New Frames, New Bottom and New topsides.

All Bedded in 3M 5200 with over 2000 screws.

The deck is about to be applied........

3/8" hydrotek 1088 7 ply. This class of runabout after the

2nd world war was not planked with mahogany. It was covered with

3/8 3 ply fir plywood and further covered with a muslin like material,

then painted with copious layers of paint. This was done to hide

imperfections and the read through of the hard & soft grain

of the fir plywood.

Tom P |

| 500th Navigator

She's ready to roll over. Bill

T |

| Mikesboat

So, I finally got started- 70 degrees

F in Atlanta today! Tempted to glue something, but it will be

too cold tonight and I still can't build indoors. That picnic

table has been used for 5 boats now!

All bulkheads cut, one set of sides and chinepanals laid out.

Think I will go out and layout leeboard, rudder, and stock next.

Bill M |

| Thanksgiving

click image for larger view

Jim Michalak once described me

in print as having "boundless energy and enthusiasm".

It's a lovely image, but I think the truth might be closer to

"stir crazy and manic". The attached photo is Thanksgiving

morning 2007 in Madison, Wisconsin. Let's just say that I have

a lot of the year to get stuff done in the shop.

--Rob Rohde-Szudy |

| Laker

My Laker

is almost completed

James H |

|

| Articles?

I'm a long-time reader of Duckworks and a subscriber (mostly

lurker) to the mailing list, writing to see if you folks might

have an interest in a series of articles about a boat in progress.

We needed a boat to use in large Maine lakes, able to be powered

by a small (current thinking is 15-20 hp) 4-stroke outboard, with

a cabin just big enough for minimal shelter and a porta-potty.

There are, of course, quite a few boats that would fit that bill,

but we have an additional requirement that eliminated my favorite--Karl

Stambaugh's camp cruiser REDWING: There's a bridge we have to

get under that allows a maximum of four feet from the waterline

to the topmost part of the boat. I looked at a lot of plans and

bought a few including two designs from Jim Michalak and one from

Wes Farmer and finally settled on a design of my own--I call it

a lake skiff--based loosely on LARK, a traditional Chesapeake

Bay skiff whose plans I got from the Chesapeake Bay Maritime Museum.

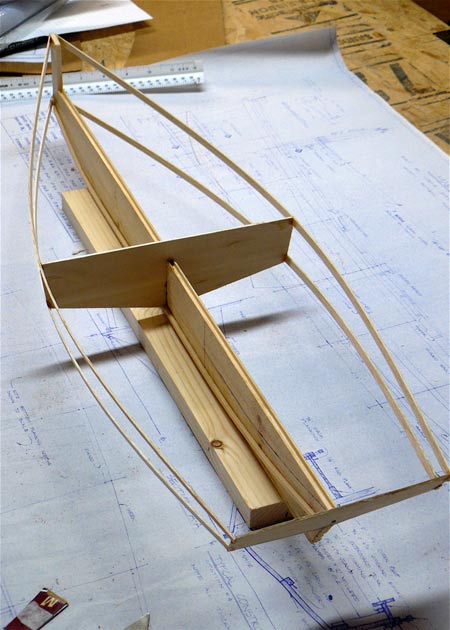

I built quite a few minimalist models (these my wife named "ghost

models" because they reminded her of the architectural "ghost

frames" of historical buildings at St. Mary's City, MD) to

evaluate hull shapes, dimensions and so forth. One of those models

is shown in the next photo.

Once I decided to incorporate a round stem in homage to the most

famous craft of our local lakes--the Grand Laker canoes--I had

to figure out how to MAKE a round stem, something I'd never had

to do on any previous projects. I came up with a stitch-and-glue

plywood construction method for what is usually a solid timber.

The model worked, so I made a full-size one.

I have quite a few photos detailing the whole process. Please

let me know if you'd like to see an actual article to get started.

I'll have a bit of time to write in the next few weeks. Thanks

much.

--Charlie E |

|

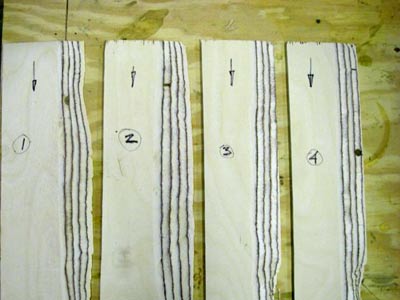

| Three Letters on

Scarfing

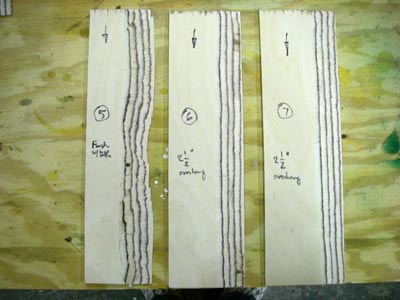

Nov 23:

Chuck,

Please look at the four scarph samples below. This is my first

attempt. The samples are 1/4" (6mm) Baltic birch labeled

in order.

The arrows show the direction of cut, leading and trailing edge.

It appears that the cut improves in uniformity somewhat but the

last two show the trailing section near the end of cut falling

apart. I don't know what I'm looking at or for and am not sure

of what a good scarph cut really looks like or what to expect

and what is acceptable.

Can you comment on this?

Thanks.

Best,

Jim

Jim: Practice makes perfect. Also you may be having trouble

with "chatter" - the edge of the plywood vibrating

as you cut the scarf - Chuck

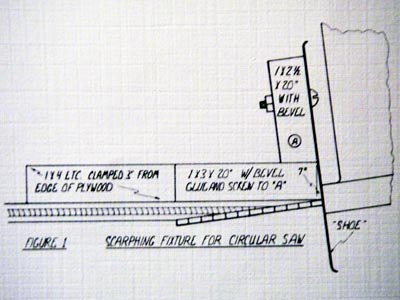

Nov 24

Chuck,

Here is a drawing photo of the scarphing fixture I built, per

instructions that came with the boat plans. This is attached to

the circle saw. The cut is done upside down.

After reading your comments about chatter, I am thinking that

maybe I shouldn't have had the plywood sheet overhanging the edge

of the cutting table. I thought the edge to be scarphed had to

be out from the table's edge several inches so the saw blade didn't

run into the table. I'm thinking that I should have clamped the

ply flush with the table's edge. Maybe the blade doesn't even

cut into the table, or much at all. This part of the procedure

wasn't mentioned in the instructions.

Thanks for your comments.

jim

Jim: it is important to secure the ply when making a cut

like this. The table is supposed to do that - Chuck

Nov 25

Chuck,

These samples photos below were done after your suggestion to

minimize chatter. No. 5 was done flush with the table with the

idea to give complete support to the ply. You can see it was the

worst of the bunch and the saw blade did indeed cut into the table

top as feared. Not good. No.'s 6 and 7 were done with the plywood

at a 2 1/2" overhang. The guide clamp for guiding the saw

fixture was clamped 1/2" in from the table edge. My idea

was to give the weight of the saw and fixture something more to

rest on. The 1/2" dimension also gave the 3" necessary

to fit the fixture's foot. The first attempt looked pretty good

to me. My concern then was repeatability so I tried it again with

the same clamping method as above. No. 7 looks very close to No.

6.

What do you think? Are No's. 6 and 7 acceptable?

I'm going to get my blade sharpened Monday. All this cutting

has started to dull it I'm sure. I didn't photograph some of the

earlier tests - which were much worse. Terrible actually.

jim

Jim: I think you have got it! There is nothing wrong with

6 and 7 above. - Chuck

|

|

|

Free Services Available to Boaters Worldwide |

Traveltrac LLC announces the Version 1 release

of Sailtrac.com to sailing, cruising, and boating enthusiasts

worldwide. Designed as a non-commercial easy to use real time

web hosting domain that integrates mapping tools, Sailtrac provides

users the ability create their own private web pages with complete

with Google maps, remote position reporting, online text journal,

and the opportunity to post photos and videos and share them with

their network of friends back home. Draw your intended route course

and actual course traveled on all bodies of water worldwide in

real time. Integrate Buoyweather reports for that date and location.

Account registration is absolutely free. No need to learn complicated

HTML or other computer programming languages. Using Sailtrac’s

step by step tutorials you can quickly and easily create your

own custom web pages. Provide friends and family back home with

peace of mind and the ability to share your adventures on the

high seas, even if it is just a weekend outing under anchor. Create

an automatic e-mail address book that instantly notifies recipients

of your last reported GPS coordinates, creates a satellite photo

map with zoom features, shares a private link to your automatically

updated Sailtrac pages sharing your private videos, photos, and

journal entries from all along your route available to your private

address book of recipients. If you so choose you can make your

pages “public” and share them with the greater Sailtrac

community.

Let Sailtrac help you host and update your own custom web pages.

It’s FREE. Create your own historic record of voyages and

travels and

share them online. Visit us at www.sailtrac.com

to learn more.

|

|

|

|

|

|