| 1 have used several

of the butt-joint methods in the past, and have been

looking for a better way to make one as strong and

invisible as possible, and I came up with the following.

This butt-joint is

made without fasteners, using just epoxy-glue, and

we want to glue more than just the surfaces together,

so this is what we did.

|

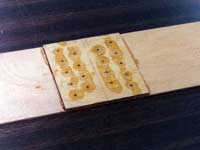

Photo 1

(click images for larger

views) |

Step One

Lay out the two panesl

of one-eighth inch plywood to be joined and also a

butt-block of the same thickness material (Photo

1)

|

Photo 2 |

Place the butt-block

over the joint, and then drill through both pieces

with a small drill bit (3/32 to 1/8 inch), in the

marked places. (Photo 2)

Step Two

|

Photo 3 |

Now we want to ream-out

the holes on the inner faces of both the panels and

butt- block to a depth of the outer ply of the plywood.

Use a reamer bit or a larger drill-bit as shown (Photo

3).

|

Photo 4 |

Now --- when glued

together we are bonding more than just the surfaces

of the plywood. We are creating a bond through all

layers of the plywood. This makes the joint stronger

and in my opinion the butt-block can be narrower and

thus less flattening of the panel at this point.

Step Three

|

Photo 5 |

We are now ready for

the epoxy. (That used in this example is from Ace-hardware)

Put the epoxy on the edge of both panels to be joined,

position them on the wax- paper, coat the surfaces

of both the panels and butt-block being sure to fill

the recessed holes. When pressing the butt-block in

position you will squeeze out through the holes the

excess epoxy, remove the excess before covering with

another piece of wax paper and adding the ten pounds

of weights (photo 4-5).

Step Four

|

Photo 6 |

|

Photo 7 |

After the epoxy has

set and is still tacky, but not hard, 1 remove the

weights and wax paper and scrape both sides of the

joint, then replace the paper and weights leaving

it until it is hard (Photo 6-7).

|

Photo 8 |

Results (Photo

8) |