Skimmer

The Poor Man's Whaler

by Dynamite Payson

(Excerpted from Messing

Around In Boats)

(click

here for more information about MAIB)

I don't suppose Skimmer would win an award purely

for looks, but for the shortest time between two points she

fills a need, and she does that handsomely. Her total cost of

$50 to $75, which represents the current tab for a couple of

sheets of plywood and a few 2x4s, justifies my calling her "the

poor man's Boston Whaler."

Watching lobsterman Don York skittering around

Spruce Head Island in a similar type of his own design first

aroused my interest in this kind of speedster. Actually, he

turned out a series of variations. His first effort was perfectly

flat bottomed with her forward end turned up like a Sea Sled's,

poor cornering and cavitation spurred him to further experimentation.

At one stage, his chariot was two Styrofoam logs in a framework

bolted to a piece of plywood on which he mounted an old fashioned

wooden kitchen chair. All you could see was Don upright in this

chair, tearing across the harbor like a bat out of hell with

water flying everywhere.

It was one of those things people are sometimes

driven to do for the good of their souls, I guess. You've got

the motor, you've got the materials, you've got the goal. So

you do it. I'm all for this kind of thing, but it's best done

with the aid of a designer. The fun of the thing kept nagging

at me and kept me nagging Phil Bolger until he gave up and designed

Skimmer.

Even so, I had plenty of critics busy making

me uneasy. Brooks Townes, then with National Fisherman,

kept telling me, "You know, you can flip one of those when

you get air trapped under her." I let Phil know of my concern

and left it to him to make the venture safe. When I got the

plans I began to wonder about the effectiveness of the three

skids along her bottom. How much lift would they give and how

much tunnel effect would they provide, as the Whaler's cathedral

hull does, to let the air escape?

An explanation accompanied the plans, from which

I gathered that the combined area of the three 1-1/2" skids

would produce quite a bit of lift, similar, for example, to

the human feet, which have performed successfully as substitutes

for water skis. Anyway, during the trial runs of the prototype,

my son Timothy drove her at a good clip with his 10 horse Mere

and I could see that she cornered very nicely. When he took

her on longer trips, such as out to the Muscle Ridge Islands,

he reported that she never showed any tendency to back up.

Materials

Two sheets 1/4" 4' x 8' AC exterior or marine

grade plywood. Four 8' 2"x4"s for bottom skids, inside

gunwales, transom framing, and bow transom Filler (optional).

20' of 3/4" pine, spruce, fir, or mahogany for chine logs

and seat framing. One 1-1/2" x 5-1/2" 8" plank

for motor support board and bow transom framing. A 5" board

for the bow transom top framing.

1 ib. of 1" #13 bronze anchor nails for

fastening chine logs to bottom. 1 lb. of 1-1/4" bronze

anchor nails for fastening bottom skids. 1 Ib. Weldwood dry

powder glue (or epoxy or marine glue of your choice, it's not

critical elsewhere, but epoxy is best for the bottom skids).

20' of 3" fiberglass tape for chines and

a short strip of wider tape or Fiberglass cloth to cover the

bow transom joint. I qt. resin and hardener.

Oarlocks, oarlock side plates, and 3/8"

x 4" bow eye. Dow Corning sheet styrofoam (blue) for rotation

under seat.

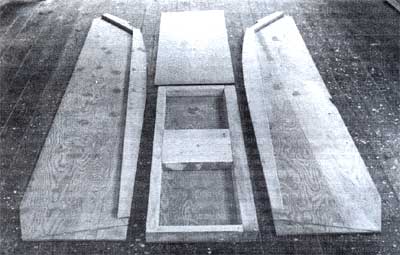

Layout And Assembly

Mark a sheet of plywood at 1' intervals as on

the plan and draw in perpendiculars to use in measuring from

the edge of the sheet to establish the shape of the sides. Define

the curve area near the bow by driving nails and springing a

batten around them. Mark sides for molding, waterline, transom

rake, seat location, and oarlock side plates. Cut the framing

for the top and sides of the stern transom from a 1-1/2"

strip, the bottom framing is 1-1/2" x 2-1/2" and is

beveled 14 degrees.

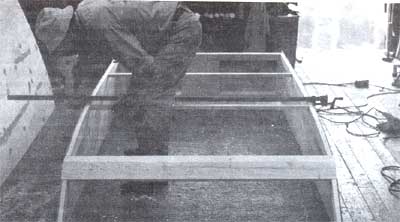

Establish the shape of the chine logs from the

sides. Lay the sides on the floor and glue and fasten the chine

logs to the inside bottom edges. Instead of the filler block

noted on the plan, use a piece of 2" x 6" plank (detail

drawing of this option is included). Let the bottom and bow

transom plywood butt at this joint and glue and fasten the hull

bottom and bow transom using 1" nails. Fasten the ends

of the plank to the chine logs, plank ends flush with the outside

of the sides. Round off to suit and apply Fiberglass tape and

resin. Fasten the bow transom top (a 3/4" x 4-1/4",

3', 11-1/2" board) to the bow transom using glue and 1"

nails.

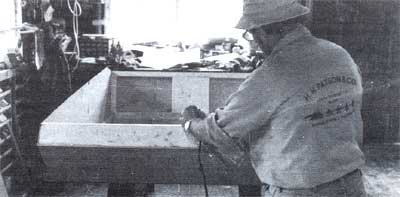

Mark the outside bottom for the locations of

the skids. Cut these from 2" x 4"s, six strips in

all, and glue them together in pairs as shown, using epoxy.

Form the curve either by securing each pair to the extreme outside

edge of the bottom before gluing, shoring in place to follow

its outline, or by constructing a jig for this curve and doing

all three at once. Let glue harden overnight and cut the fore

and aft taper the next day.

Bore pilot holes for skid fastenings through

the bottom, glue skids with epoxy, and fasten them from the

inside with 1-1/4" anchor nails, shifting to the 1"

nails in the tapered sections.

Turn lhe boat right side up. Install the inside

gunwales, sheer moldings, quarter knees, and seat frame. Pack

Styrofoam flotation under the seat. Install the 1- 1/2"

x 3-1/2" backing block for bow eye.

The only change I made in the original plans,

with Phil's approval, was in the bow joint, which catches the

lower edge of the bottom as described in the option noted above.

This is simpler and faster and it makes for better nailing than

using the 3/4" x 5-1 /2" framing as originally drawn

and adding a filler piece.

There are no bugs in building Skimmer. The hardest

part is getting the correct bend in the skids and holding it.

I bent and glued two pieces of 1-1/2" x 3/4" spruce

together and clamped them to the outside edge of the bottom

to conform to that shape until the glue dried, one set of skids

to each side. I clamped the third set to a jig, taken off the

shape of Skimmer's bottom. The next day I tapered their forward

ends and fastened them on, nailing from inside while a helper

backed the skids up with a heavy maul from the outside.

Click image to enlarge

Skimmer is a very stable platform, stable enough

to stand up and fish from. 10 hp to 15 hp is just right for

Skimmer. Don't put on any more unless you want to scare yourself

half to death.

Plans are $30 a set, from H.H.

Payson, 31 Pleasant Beach Rd, S. Thomaston ME 04858.